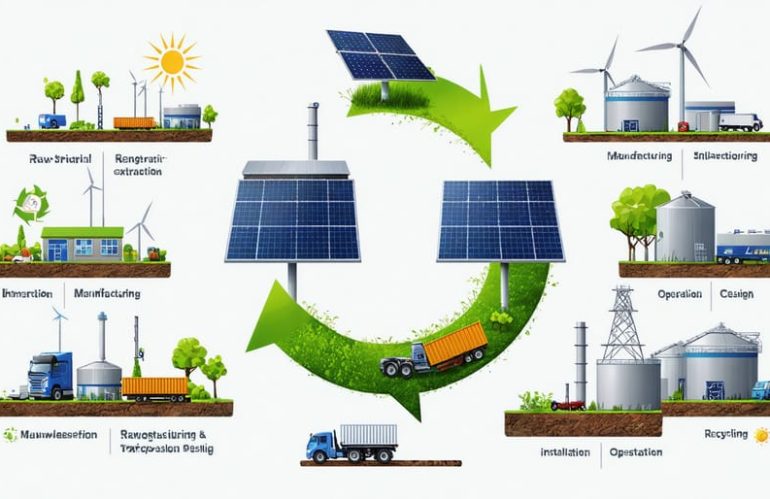

As solar panels increasingly power our transition to renewable energy, understanding their complete environmental impact requires examining more than just their clean electricity generation. From raw material extraction to end-of-life recycling, solar panels’ life cycle tells a complex story of energy investment, resource consumption, and long-term sustainability. This comprehensive analysis reveals that while manufacturing solar panels does create an initial carbon footprint, most panels offset their environmental impact within 1-4 years of operation, going on to provide decades of clean energy production.

Modern solar panels typically last 25-30 years, generating approximately 20-30 times the energy used in their production. Yet their true environmental impact encompasses the entire journey – from mining silicon and rare earth elements, through energy-intensive manufacturing processes, to installation, maintenance, and eventual recycling. Understanding this complete lifecycle helps homeowners and environmental advocates make informed decisions about solar energy while highlighting crucial areas for industry innovation and improvement.

Raw Material Sourcing: The First Step

Silicon Processing

The journey of a solar panel begins with silicon, one of Earth’s most abundant elements found primarily in sand and quartz. To transform this raw material into the foundation of solar panels, manufacturers first extract high-purity quartz and heat it with carbon in special furnaces at temperatures reaching 3,600°F. This process creates metallurgical-grade silicon, which is about 98% pure.

However, solar panels need even purer silicon to function effectively. The material undergoes additional refinement through a chemical process called the Siemens method, which produces electronic-grade silicon that’s 99.9999% pure. This ultra-pure silicon is then melted and carefully crystallized into ingots, which are sliced into the thin wafers that form the basis of solar cells.

While this process is energy-intensive, it’s worth noting that a solar panel typically generates enough clean energy in 1-2 years to offset the energy used in its silicon processing. This efficient energy payback makes solar panels a sustainable choice for homeowners committed to reducing their carbon footprint.

Metal and Glass Components

Beyond silicon, solar panels incorporate several metal and glass components that play crucial roles in their functionality. The aluminum frame provides structural support while protecting the internal components from the elements. High-quality tempered glass covers the front of the panel, allowing sunlight to pass through while shielding the cells from damage. Inside, copper wiring creates the electrical connections that carry the generated power.

The sourcing of these materials has become increasingly sustainable. Manufacturers are now using recycled aluminum and glass in their production processes, significantly reducing the environmental impact. Copper, while primarily mined, can be recycled indefinitely without losing its conductive properties. Many leading solar companies have established partnerships with responsible suppliers who prioritize sustainable mining practices and fair labor conditions.

The good news is that all these components can be effectively recycled at the end of a panel’s life, making solar technology increasingly circular in its lifecycle.

Manufacturing Process and Energy Use

Energy Requirements

The energy required to produce solar panels has decreased significantly over the years, thanks to improved manufacturing processes and technology. On average, it takes about 2-3 years for a solar panel to generate the same amount of energy that was used in its production – this is known as the energy payback period. Most of this energy consumption occurs during the silicon purification and cell manufacturing stages.

Modern solar panel factories typically use between 2,000 and 2,500 kilowatt-hours of energy to produce a single solar panel. This might sound like a lot, but consider that the same panel will generate between 6,000 and 8,000 kilowatt-hours of clean energy during its first decade of operation alone. Many manufacturers are also transitioning to renewable energy sources for their production facilities, further reducing the carbon footprint of solar panel manufacturing.

The good news is that solar panels continue producing clean energy for 25-30 years after installation, making their lifetime energy output significantly higher than the initial energy investment. This positive energy balance makes solar panels an environmentally sound choice for homeowners looking to reduce their carbon footprint.

Manufacturing Emissions

The environmental cost of production for solar panels primarily comes from energy-intensive manufacturing processes and raw material extraction. While these emissions are significant, it’s important to understand that they represent a one-time environmental investment that typically pays off within 1-4 years of solar panel operation.

The average solar panel manufacturing process generates about 40-50 grams of CO2 per kilowatt-hour of electricity produced over its lifetime. This figure includes emissions from silicon purification, panel assembly, and transportation. However, these numbers continue to improve as manufacturers adopt cleaner energy sources and more efficient production methods.

Many leading solar manufacturers now power their facilities with renewable energy, significantly reducing the carbon footprint of new panels. Some companies have achieved up to 80% reduction in manufacturing emissions compared to traditional methods. This progress means today’s solar panels are cleaner to produce than ever before, making them an increasingly attractive option for environmentally conscious homeowners looking to reduce their carbon footprint.

Transportation and Installation Impact

The journey of solar panels from factory to rooftop involves careful planning to minimize environmental impact. Most panels travel by sea freight from manufacturing facilities to local distribution centers, which is more eco-friendly than air transport. While shipping does contribute to the carbon footprint, manufacturers optimize container space and often use fuel-efficient vessels to reduce emissions.

Once panels arrive at their destination, local installation teams typically use standard work vehicles to transport them to homes. While these vehicles do produce emissions, the impact is relatively small compared to the overall environmental benefits the panels will provide. Many installation companies are now transitioning to hybrid or electric vehicles for their crews, further reducing transportation-related emissions.

The installation process itself has minimal environmental impact. Modern mounting systems require few roof penetrations, and most installations can be completed in just one or two days. The main environmental considerations during installation include proper disposal of packaging materials and careful handling of any electrical components.

To reduce waste, many installers now participate in recycling programs for packaging materials and work with suppliers who use minimal, recyclable packaging. Some companies even offer innovative solutions like reusable panel crates that can be returned to manufacturers, creating a closed-loop system that further minimizes environmental impact.

Overall, while transportation and installation do contribute to solar panels’ carbon footprint, these impacts are relatively minor and are quickly offset by the clean energy the panels produce.

Operational Benefits and Energy Payback

Once installed, solar panels begin delivering immediate environmental dividends, making their overall environmental benefits particularly compelling. The energy payback time – the period required for panels to generate the same amount of energy used in their production – is remarkably short, typically ranging from 1 to 4 years depending on the location and panel type.

During their operational lifetime of 25-30 years, solar panels generate clean electricity without producing greenhouse gas emissions or air pollutants. A typical residential solar system can offset approximately 100,000 pounds of carbon dioxide over its lifetime – equivalent to planting over 50 trees. This significant reduction in carbon footprint helps combat climate change while providing homeowners with reliable, renewable energy.

The operational benefits extend beyond environmental impact. Modern solar panels require minimal maintenance, typically just occasional cleaning and basic inspections. They operate silently, have no moving parts, and can withstand various weather conditions, making them a reliable source of clean energy for decades.

From a financial perspective, solar panels consistently generate free electricity after installation, reducing or eliminating monthly utility bills. Many homeowners see complete energy cost recovery within 5-10 years, after which the savings continue to accumulate. Additionally, solar panels can increase property values and provide protection against rising energy costs, making them a sound long-term investment for environmentally conscious homeowners.

End-of-Life Recycling and Disposal

As solar panels reach the end of their 25-30 year lifespan, proper disposal and recycling become crucial for maintaining their environmental benefits. Modern solar panel recycling processes can recover up to 95% of materials, including valuable components like silver, silicon, and aluminum. Most manufacturers now offer take-back programs, making it easier for homeowners to responsibly dispose of their old panels.

The recycling process typically involves separating the aluminum frame, removing the glass cover, and extracting the silicon cells and metal components. These materials are then processed and reused in new solar panels or other products, creating a circular economy that reduces waste and conserves resources.

Looking ahead, emerging technologies are making recycling even more efficient and cost-effective. Industry experts predict that as more panels reach end-of-life, improved recycling infrastructure and automated processes will make panel disposal increasingly sustainable. This development ensures that your investment in solar energy continues to benefit the environment long after the panels have served their primary purpose.

Despite their initial environmental impact during manufacturing, solar panels prove to be a remarkably sustainable energy solution. Over their 25-30 year lifespan, they generate clean electricity that far outweighs their carbon footprint, typically reaching their environmental break-even point within 2-4 years. For homeowners, solar panels not only reduce carbon emissions but also offer substantial financial returns through reduced energy bills and potential tax incentives. With improving recycling technologies and manufacturing efficiencies, solar panels continue to become even more environmentally friendly. This makes them an excellent investment for both the planet and your wallet, delivering decades of clean, renewable energy while significantly reducing your household’s carbon footprint.